Trina Solar’s 210mm Vertex Modules Achieve Excellent Test Results in the PVEL Product Qualification Program

Dubai, United Arab Emirates – December 23rd – At the BloombergNEF Summit held in early December, PV Evolution Labs (PVEL), a world-renowned third-party reliability testing laboratory, shared excellent reliability and performance test results for Trina Solar’s 210mm Vertex modules. The selection of ultra-high power Vertex modules that were evaluated by PVEL represent specific bills of materials (BOMs) that were independently witnessed during production. In particular, the tested BOMs showed superior performance in PVEL’s Mechanical Stress Sequence (MSS) and Thermal Cycling 600 (TC600) tests, which directly relate to the changes in module sizes. Testing did not produce micro-cracks in the 550W and 670W dual-glass BOMs evaluated by PVEL. The power degradation rates after testing was less than 2%, which meets the Top Performer criteria defined by PVEL for its 2021 PV Module Reliability Scorecard.

PVEL-PQP conducts more stringent test over Trina’s Vertex

PVEL is the world’s leading PV module reliability testing laboratory, which provides independent performance data for solar project developers, financiers, and asset owners and operators around the world. In 2012, PVEL launched the PQP for stringent testing of PV modules on reliability & quality parameters, that are significantly more rigorous than the IEC standards. All BOMs submitted to PQP for tests must undergo inspection during production and be sealed by PVEL auditors at the factory to ensure that the test results objectively reflect the level of mass-produced modules with the same BOM. With over ten years of experience and accumulated data, PVEL conducts testing as a key reference for a brand’s bankability level, enabling efficient solar project development and financing.

MSS test: No micro-cracks occurred in ultra-high power Vertex modules!

When PV modules are exposed to mechanical loads in the field such as heavy snow or forces caused by strong winds, hail, etc., their components will be pressed and break as a result, which may cause a number of degradation issues that reduce module performance.

PVEL’s Mechanical Stress Sequence (MSS) simulates this process. MSS combines tests for static mechanical load (SML), dynamic mechanical load (DML), thermal cycling (TC) and humidity freeze (HF). It is one of the most stringent PQP sequences and PVEL has multiple examples of modules breaking during the test.

Mechanical Stress Sequence (MSS)

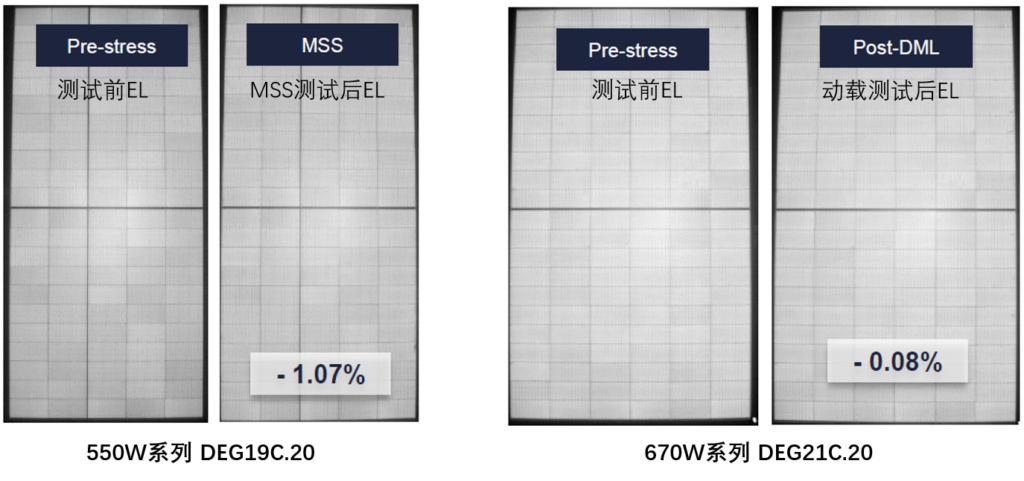

Test results demonstrate no micro-cracks occurred in the BOMs tested for Trina Solar’s 210mm Vertex dual-glass 550W modules, and the power degradation was only 1.07%. As for the 670W dual-glass module BOM, the SML and DML testing phases have been completed and the interim data again show that the modules have excellent performance, with no micro-cracks and close to zero (-0.08%) power degradation. Trina Solar’s Vertex ultra-high-power modules of larger formats maintain excellent mechanical load performance against micro-crack.

A comparison of EL before and after MSS

TC600 test: Vertex 550W+ modules suffer nearly zero power degradation

During the 25-year life cycle of a solar power station, the material components of PV modules expand and contract thousands of times. The TC (thermal cycling) test sequence is intended to find out whether temperature cycling can cause excessive interface stress, which may damage modules and weaken system performance. In the PQP test sequence, modules are placed in an environmental chamber at extreme temperatures, lowered to -40°C, then increased to 85°C with maximum power current flowing through. This cycle is repeated 200 times over three periods, to a total of 600 cycles, which is three times the IEC standard requirement.

TC600 test

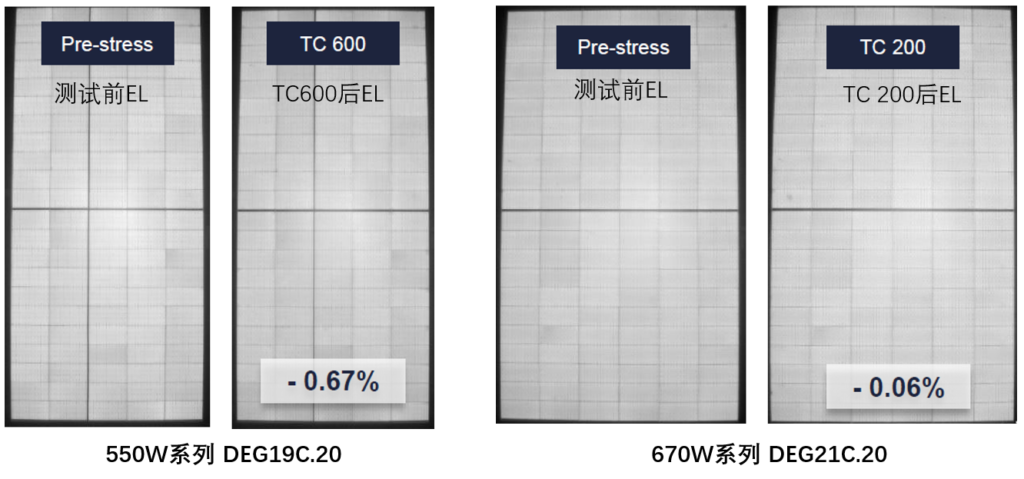

The results show that the BOMs tested for Trina Solar’s Vertex ultra-high-power modules have excellent resistance to external temperature variations and have a robust and reliable structure. No micro-cracks occurred in the 550W dual-glass model BOM tested by PVEL, and the power degradation was only 0.67%. As for the test of the 670W dual-glass model BOM, 200 cycles have been completed so far, with interim data of no micro-cracks and close to zero (-0.06%) power degradation.

A comparison of EL before and after TC600

In summary, the mechanical stress sequence and thermal cycling test results for the PVEL-tested BOMs of Trina Solar’s Vertex ultra-high power modules suggest that they are not impaired after thermal cycling and mechanical stress due to their larger formats, instead maintaining top performance and ensure mechanical reliability.

Precisely because of the strong performance of its products in reliability tests, Trina Solar has been awarded as Top Performer in PVEL’s Scorecard for seven consecutive years.

About Trina Solar (688599. SH)

Founded in 1997, Trina Solar is the world leading PV and smart energy total solution provider. The company engages in PV products R&D, manufacture and sales; PV projects development, EPC, O&M; smart micro-grid and multi-energy complementary systems development and sales, as well as energy cloud-platform operation. In 2018, Trina Solar launched its Energy IoT brand, established the Trina Energy IoT Industrial Development Alliance together with leading enterprises and research institutes in China and around the world, and founded the New Energy IoT Industrial Innovation Center. With these actions, Trina Solar is committed to working with its partners to build the energy IoT ecosystem and develop an innovation platform to explore New Energy IoT, as it strives to be a leader in global intelligent energy. In June 2020, Trina Solar listed on the STAR Market of Shanghai Stock Exchange. For more information, please visit www.trinasolar.com

For media inquiries please contact:

Fekra Communications

Lojayne Mohsen

M: +971 52 7706706